Sustainability

What we mean by sustainability

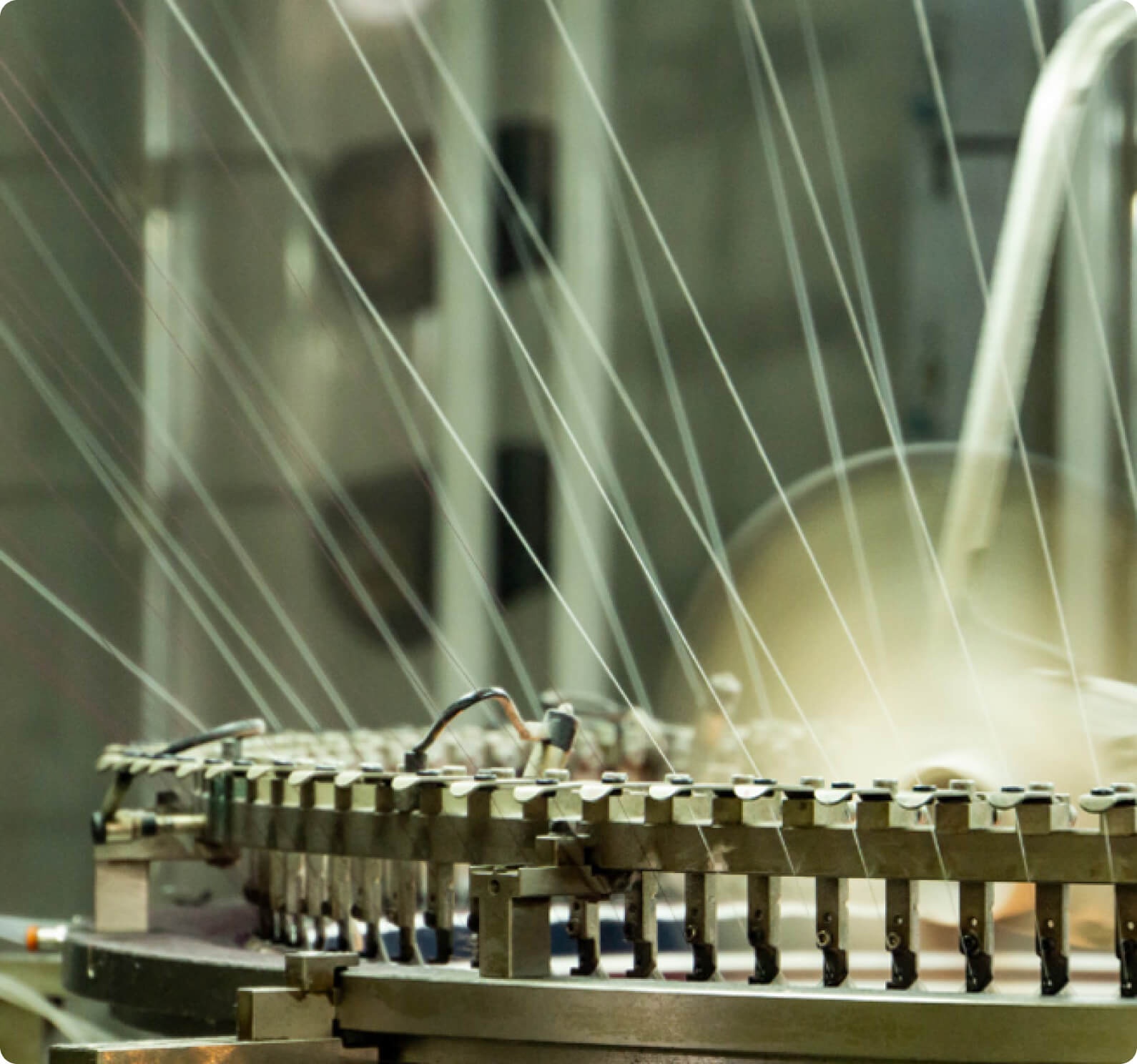

The first step in the production of fibers for clothing manufacture is the production of yarn from the raw materials. Here fibers are pulled out with a spinning wheel and twisted in order to produce continuous yarn. Fibers are drawn across the wheel and as it rotates, fibers are collected onto a cylindrical object called a spool.

We buy yarns that have already been processed and use them to make the fabric. Cotton yarns we buy come from GOTS certified manufacturers in India, while recycled polyester yarns come from Spain.

The yarn purchased goes to our partner Nuno in the Santo Tirso region of Portugal. Here individual threads are joined together to form a fabric. The process of making cloth is called weaving and requires two sets of yarn. The first set, called the warp set, is stretched taut over a metal frame. The second, called the weft, is connected to metal rods, with one thread per rod. Then the machine ties these yarn sets together by forming the fabric. Freshly woven fabric is not like what you know as clothing. Because before that, the fabrics have to be cleaned of oils, waxes and all other elements that occur naturally in most fibers. Only after this cleaning can the fabric be used by our clothing manufacturers.

Coloring if necessary

Once you have decided on a colour, we will ship the fabric to our dye partner to give the fabric the color you want.

A dyeing process describes the interaction between a dye and a substance. This consists of three phases: transfer of the dye to the fiber surface, diffusion of dye into the fiber and fixation. The accumulation of the dye in the fiber is gradual and depends on the concentration of the dye, the temperature and the presence of electrolytes.

More

Sustainably Produced

We produce fair and sustainable. A promise for the environment.

Quality

Since we do not things half-heartedly, we guarantee the best quality.

Individually Customizable

Design your merch from scratch, just the way you like.

Fair in Europe

All of our merch is produced in the EU under fair conditions.

Get in touch!

Don’t hesitate to contact us with your questions. We would love to get to know you. Fill out our contact form or book a video call with our team.

Contact